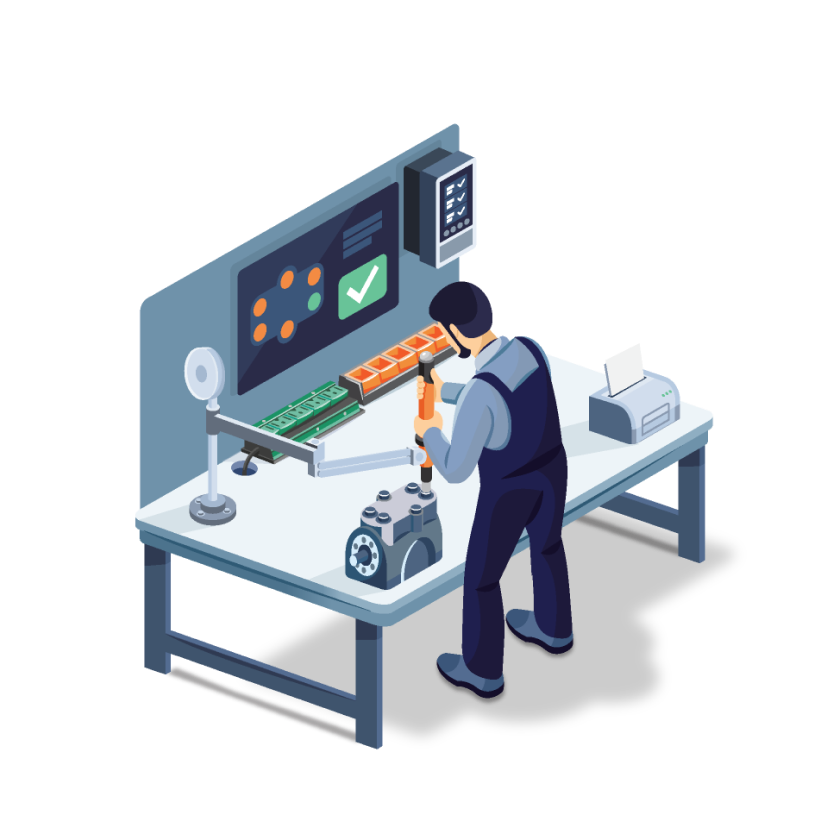

Keep your assembly process under control

Visualization and control of assembly processes with MITIGHT. Ensures proper course of operations and correct tightening sequences.

Can be supplemented by checking screwdriving positions, tool checking, connection to pick to light system and many other functions including insertion of special operations such as manual operations with confirmation button, pressing etc. It enables process control for multiple tools and different manufacturers. INGERSOLL-RAND controlled screwdrivers can work in one assembly process with STAHLWILLE torque wrenches. Password-protected access and tool locking with NOK. Special function buttons: skip screw, step back, reset assembly, change operator.

Torque arm

Simple control of screwdriving positions by detecting the position of the arm.

Trays

Control of the correct socket selection and the possibility of connection to the Pick to Light systems.

Display

Clear visualisation of the assembly process.

Control unit

We can connect any controlled tool with the possibility of data control and data collection to the MIT system.

Screwdriver

Connect one or more tools into a single procedure.

TISK app

Automatic printing of documents, data search in the database.

Simple and intuitive setup and, mainly very easy to creation of the assembly process.

We have been developing the MITIGHT system for almost 10 years and have completed many implementations that have helped us to design the system to meet the vast majority of your requirements and if there is a feature that you cannot do without, we will be happy to prepare custom modifications exactly according to your requirements.

Settings mode

New Product Mode

MIT Software Benefits

Our hardware

Modules customized for each of your unique projects.

Together with the MITIGHT software we can offer our wrench trays equipped with two LEDs for each position and BALUFF sensors. Blue LED for guidance, green LED for confirmation. Arms with integrated position sensors. I/O boxes and modules can be customized for each of your unique projects.

For customers

Manage assembly processes at no additional cost.

Are you preparing an assembly project that requires visualization and process control, data storage, and the possibility of flexible process changes? Use the MITIGHT system. You get a complete tool for process control. With no programming knowledge, you can add, change and manage your assembly processes at no additional cost.

For dealers

Working on a project where MITIGHT could be applied?

Are you a tool dealer working on a project where our system could be applied? We have very beneficial conditions for traders. Fill out the form and briefly describe your application and the tools you are considering using, we will be happy to send you a detailed information about the system including terms and conditions.

For tool manufacturers

Add your tools to our system.

Gain a distinct advantage and add your tools to our MITIGHT system. We will be happy to arrange cooperation and introduce your communication protocols into our system, which is already widely used.